- Cross-wedge rolling lines for the production of forgings for stamping from aluminum alloys

- Business and mission

- Reference List

- Media Gallery

- Partners

- News

- Main/

- About company/

- Archive/

- News

Cross-wedge rolling lines for the production of forgings for stamping from aluminum alloys

22.09.2025

Cross-wedge rolling lines for the production of forgings for stamping from aluminum alloys

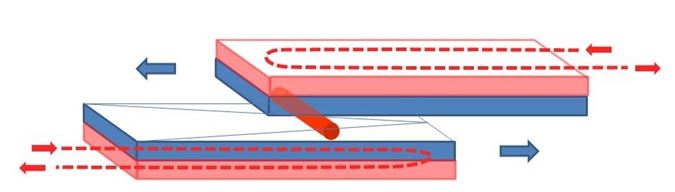

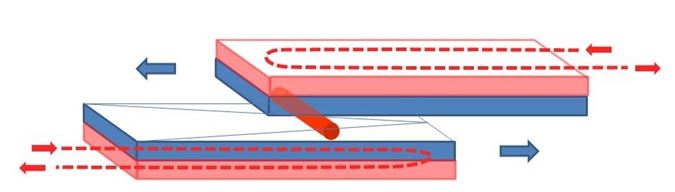

Modern forging production of aluminum alloy products requires 100% temperature control, as well as minimizing waste and stamping operations, to achieve the highest quality parts. This article explores the advantages of implementing cross-wedge rolling mills and lines with induction heating for the mass production of aluminum forgings. It also examines the advantages of using flat cross-wedge rolling technology compared to forging rolls, which are often used in the production of aluminum alloy parts.

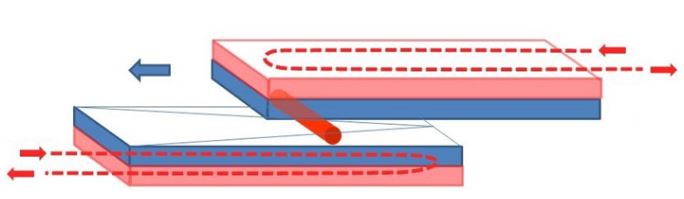

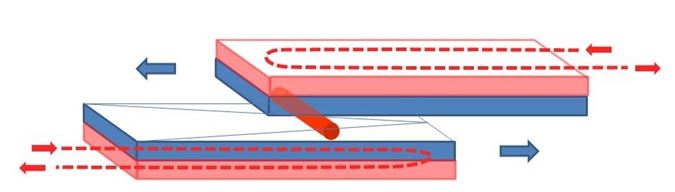

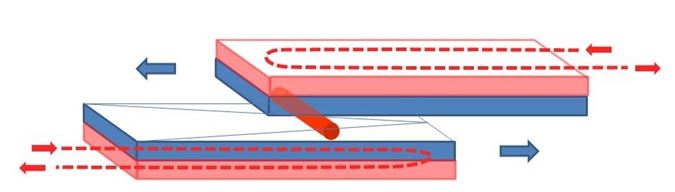

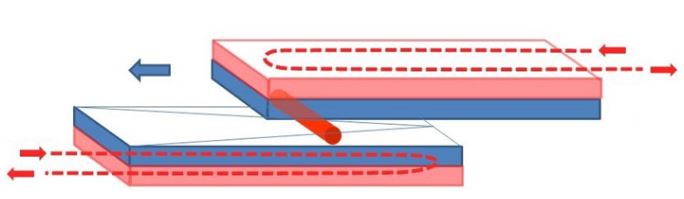

We invite you to consider the advantages of implementing cross-wedge rolling mills and lines for the production of aluminum alloy forgings. Our company's cross-wedge rolling mills feature specialized solutions and designs for rolling aluminum and other alloys. To prevent forgings from cooling during the rolling process, the cross-wedge rolling mill features increased ram(s) speed, and the rolling tool is additionally heated, unlike when rolling steel blanks, which requires additional cooling. Flat rolling tools ensure better positioning of the blank during rolling, improving forging accuracy, eliminating the need for additional calibration (this is especially important for parts intended for subsequent machining).

What is the best method for producing aluminum alloy forgings: forging rolls or cross-wedge rolling?

Cross-wedge rolling technology has fewer process limitations than forging rolls due to the ability to select the optimal forming tool length. Cross-wedge rolling allows for multiple simultaneous penetrations across the entire surface of the workpiece, eliminating the need to leave space for a workpiece holding mechanism, allowing the rolled workpiece volume to approximate the final forging volume. The high precision of the resulting forgings allows for a significant reduction in the initial workpiece volume. The introduction of cross-wedge rolling mills for rolling aluminum forgings reduces waste by 20-40% compared to forging rolls, an excellent result for rolling expensive non-ferrous alloys. Furthermore, by reducing flash waste during stamping from cross-wedge rolled forgings, tooling wear is reduced. Fine-tuning and coordinating rolling and stamping tooling is another process that allows for further waste reduction and improved overall process efficiency. Cross-wedge rolling technology is a flexible tool for improving the production of forgings for stamping and stamping in mass production, where metal utilization can be increased to 0.7-0.95.

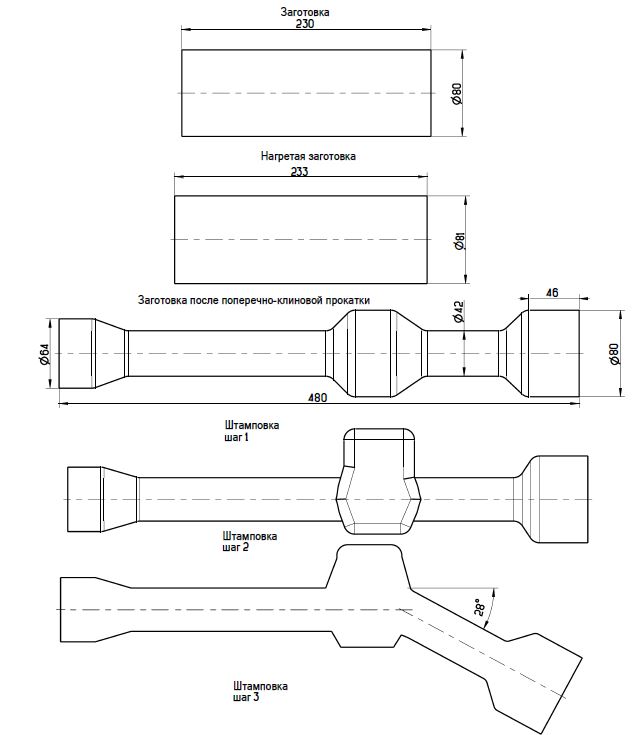

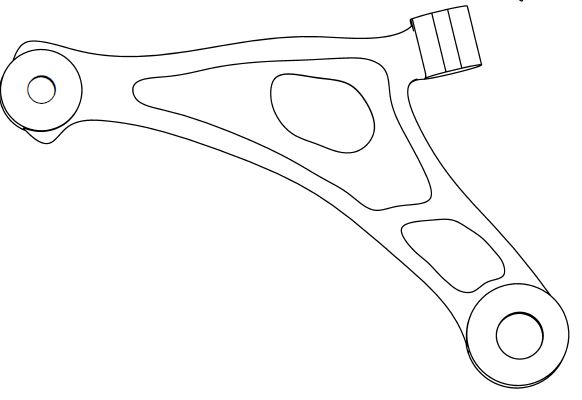

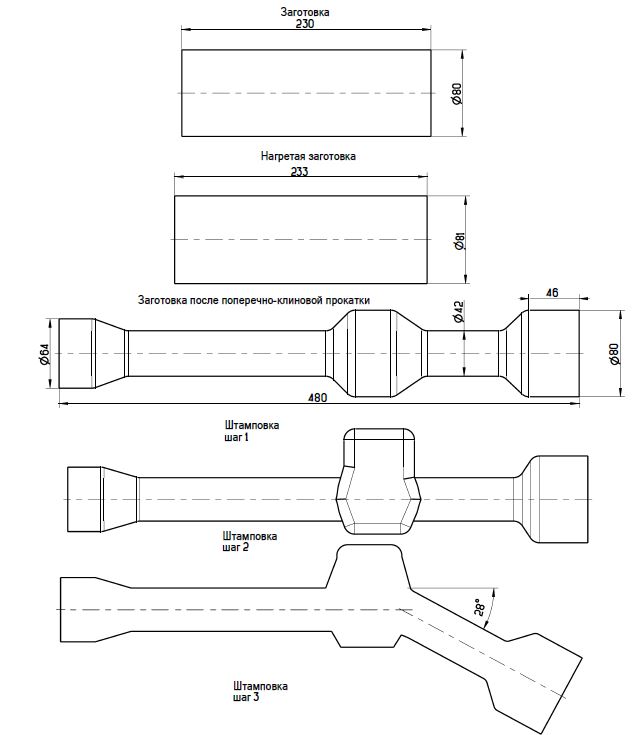

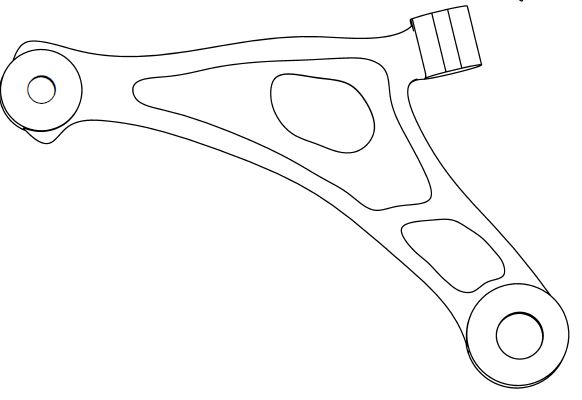

An example of an aluminum alloy forging produced using flat cross-wedge rolling technology for stamping a car suspension arm.

A variant of the lever production process with the introduction of flat cross-wedge rolling technology

Our company's cross-wedge rolling mills are designed for 2-3 shift operation, which ensures adherence to the "lean manufacturing" philosophy in serial production. By selecting the right rolling mill operating modes, ensuring 100% control of the workpiece heating temperature, and using wear-resistant tooling and technology, we can save large volumes of material, which in turn reduces manufacturing costs while adhering to the entire production process.

A line of rolling mills has been developed for rolling aluminum forgings with diameters less than 60 mm and up to 130 mm (equipment can be designed for other blank and forging sizes). For rolling aluminum forgings with diameters less than 60 mm and up to 130 mm, we offer three cross-wedge rolling line options:

1. PKP Line – WRL6014 (without INU). Installed capacity: 74 kW. Rolling cycle: 8 sec;

Maximum finished rolled product size:

Diameter Ø 60 mm

Length up to 420 mm

2. PKP Line – WRL10025TS (without INU). Installed capacity: 190 kW; Rolling cycle: 10 sec;

Maximum finished rolled product size:

Diameter Ø 100 mm

Length 630 mm

3. PKP Line – WRL13030TS (without INU). Installed capacity: 210 kW; Rolling cycle: 12 sec;

Maximum finished rolled product size:

Diameter Ø 130 mm

Length 800 mm

The equipment can be supplied with induction heating units for workpieces and an automatic feeding system of our own production; it is possible to manufacture equipment for heating the Customer's workpieces.

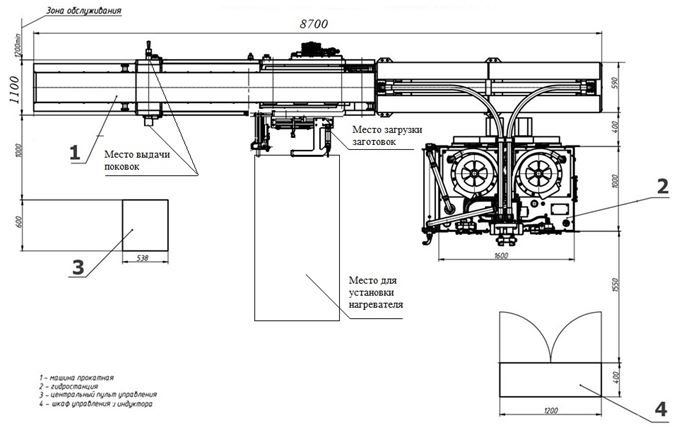

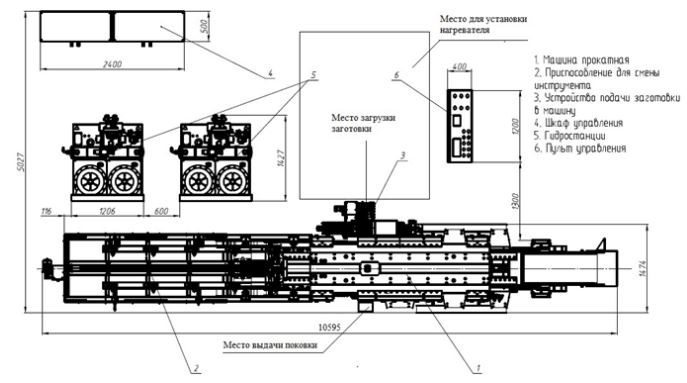

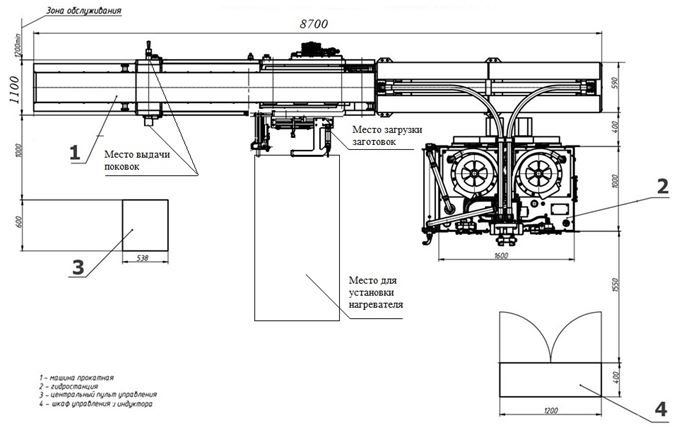

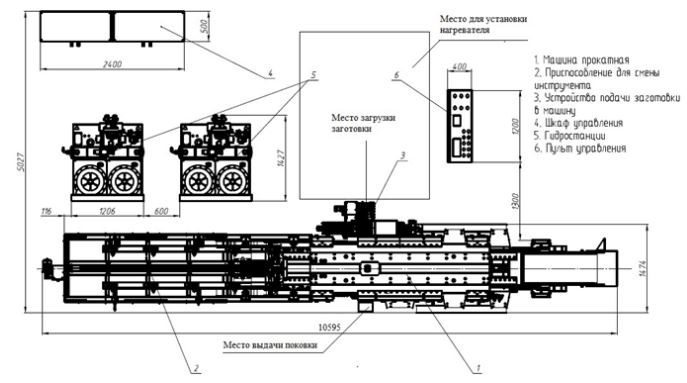

1. Layout solution for line WRL6014 (without INU)

- The line can handle a variety of tools. Each part type has its own set of upper and lower flat forming tools. The blank is formed by rolling it between the moving upper and stationary lower rolling tools, giving it the desired geometry.

- Rolling cycle: 8 seconds.

- The WRL6014 line operates using a single hydraulic station, which controls the hydraulic drive for the main machine movement (the forward and reverse stroke of the ram with the upper rolling tool; the lower rolling tool is stationary). The machine's installed power is 74 kW. Used top quality hydraulics component and brands..

- Tool changeover time is approximately 15-25 minutes.

- Maximum finished rolled product size:

- Diameter Ø 60 mm

- Length up to 420 mm

- Air up to 20 m³/hour at a pressure of 0.4…0.6 MPa. Air is used for the pneumatic cylinders and the main part for blowing off the tool. Used top quality pneumatic component and brands.

- Water flow rate for cooling hydraulic power units and other components is up to 10 m³/hour. Water pressure is 0.25-0.4 MPa. The inlet water temperature is no more than 25°C.

- The rolling machine control system is typically based on Mitsubishi controllers and PLCs or an Allen Bradley controller (for the US market) and consists of a mobile control panel and an electrical cabinet. Switchgear, cables top quality component and brands.

- Geared motors top quality component and brands.

- The control system's electrical equipment must be housed in RITTAL enclosures with a protection rating of at least IP55.

- Power supply: 380V, 50Hz (480V, 60Hz for the US market).

- Expected tool life (depending on operating conditions and the parts being rolled):

- For rolling aluminum blanks, the line is equipped with additional tool heating.

- The programmable controller-based control system enables the line to operate in setup and automatic modes, with all settings displayed on the operator panel.

- High degree of automation. Ensures smooth and stable line operation with full control of all parameters (including the induction heater, blank heating temperature control and rejection or infeed, cyclic blank feeding from a slide hopper, forging rolling, and transfer to the next production stage).

- Line weight: 9,000 kg

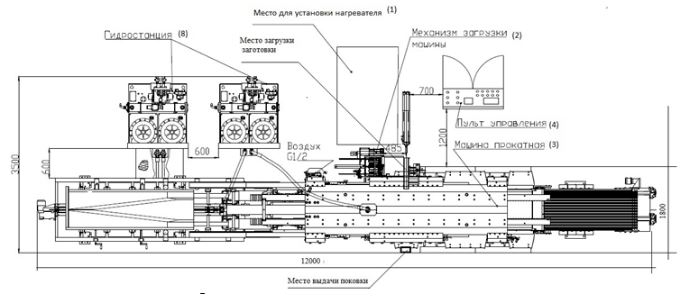

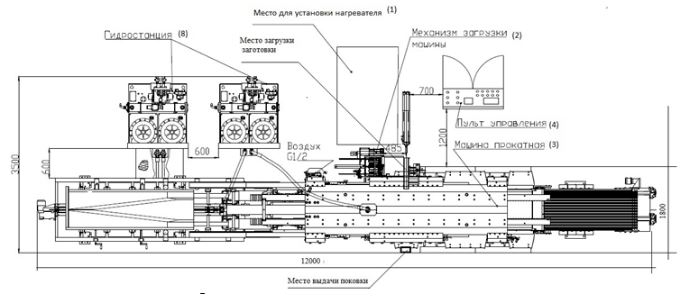

2. Layout solution for the WRL10025TS line (without INU)

- The line can handle a variety of tools. Each part type has its own set of upper and lower flat forming tools. The blank is formed by rolling it between tools moving toward each other, giving it the required geometry.

- Rolling cycle: 10 seconds.

- The WRL10025TS line operates using two hydraulic stations, which control two hydraulic drives for the main machine movement (the working and return strokes of the two sliders with the upper and lower rolling tools). The working stroke of the sliders is counter-moving. The machine's installed power is 190 kW. Used top quality hydraulics component and brands.

- Tool change time: ≈ 20-30 min

- Maximum finished rolled product size:

- Diameter Ø 100 mm

- Length 630 mm

- Air up to 20 m³/hour at a pressure of 0.4...0.6 MPa. Air is used for the pneumatic feed cylinders and the main part for blowing off the tool. Used top quality pneumatic component and brands.

- Water consumption for hydraulic stations and other components: Up to 10 m³/hour. Water pressure 0.25-0.4 MPa. Inlet water temperature – no more than 25°C.

- The rolling machine control system is typically based on Mitsubishi controllers and PLCs or an Allen Bradley controller (for the US market) and consists of a mobile control panel and an electrical cabinet.

- Switchgear, cables top quality component and brands..

- Geared motors top quality component and brands.

- The control system's electrical equipment must be housed in RITTAL enclosures with a protection rating of at least IP55.

- Power grid specifications: 480V, 60Hz (for the US market).

- Expected tool life (depending on operating conditions and rolled parts):

- For rolling For aluminum blanks, the line provides additional heating of the tool.

- The programmable controller-based control system enables the line to operate in setup and automatic modes, with all settings displayed on the operator panel.

- High degree of automation. Ensures smooth and stable line operation with full control of all parameters (including the induction heater, blank heating temperature control and rejection or infeed, cyclic blank feeding from a slide hopper, forging rolling, and transfer to the next production stage).

- Line weight: 26,000 kg

3. Layout solution for the WRL13030TS line (without INU)

- The line can handle a variety of tools. Each part type has its own set of upper and lower flat forming tools. The blank is formed by rolling it between tools moving toward each other, giving it the required geometry.

- Rolling cycle: 12 seconds.

- The WRL13030TS line operates using two hydraulic stations, which control two hydraulic drives for the main machine movement (the working and return strokes of the two sliders with the upper and lower rolling tools). The working stroke of the sliders is counter-moving. The machine's installed power is 210 kW. Used top quality hydraulics component and brands.

- Tool change time is approximately 20-30 minutes.

- Maximum finished rolled product size:

- Diameter Ø 130 mm

- Length 800 mm

- Air up to 20 m³/hour at a pressure of 0.4...0.6 MPa. Air is used for the pneumatic feed cylinders and the main part for blowing off the tool. Used top quality pneumatic component and brands..

- Water consumption for hydraulic stations and other components: Up to 10 m³/hour. Water pressure 0.25-0.4 MPa. Inlet water temperature – no more than 25°C.

- The rolling machine control system is typically based on Mitsubishi controllers and PLCs or an Allen Bradley controller (for the US market) and consists of a mobile control panel and an electrical cabinet.

- Switchgear, cables top quality component and brands..

- Geared motors top quality component and brands.

- The control system's electrical equipment must be housed in RITTAL enclosures with a protection rating of at least IP55.

- Power grid specifications: 480V, 60Hz (for the US market).

- Expected tool life (depending on operating conditions and rolled parts):

- For rolling For aluminum blanks, the line provides additional heating of the tool.

- The programmable controller-based control system allows the line to operate in setup and automatic modes, with all settings displayed on the control panel.

- High degree of automation. Ensures smooth and stable line operation with full control of all parameters (including the induction heater, blank heating temperature control and rejection or infeed control, cyclic blank feeding from a slide hopper, forging rolling, and transfer to the next production stage).

- Line weight: 32,000 kg

If you are interested in installing a cross-wedge rolling line for rolling forgings for stamping parts made of aluminum alloys (rolling of other alloys is also possible), we provide preliminary calculations of the workpiece volume, forging dimensions, and 3D modeling of the rolling and stamping process.

We design and manufacture cross-wedge rolling mills and rolling tools in-house. We can supply the line complete with an induction heating unit for the workpieces and automated feeding, inspection, and inspection of the workpieces. We also perform commissioning on-site.

t. +375-17-500-31-13

f. +375-17-500-31-32

+375255001523 (Viber, WhatsApp)

amtengine@amtengine.com